Green Tea Production: Baking

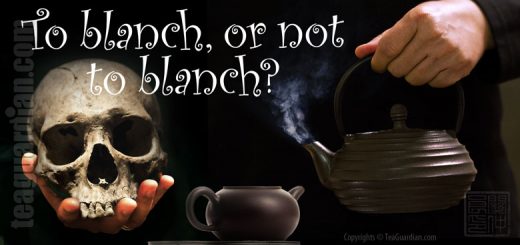

Traditional tea baking basket

The cement drums underneath are stoves where charcoal ashes are used as fuel. The whitened areas on the baskets are joints between the top basket and the lower ones. Tea leaves go on the top layer only. Notice how dark the bamboo stripes have become.

Using heat to dry tea is as old as, if not older than, the method of steaming. As described in ancient writings, tea was dried by baking after steaming. The idea is the same in the modern method. The steamed and shaped tea is passed through ovens to dry. To skip steaming in production, however, takes a slightly different approach.

etymology

There are a few words in Chinese that may mean “to bake”. In tea production, the word “bei” is used generally for drying with heat, and the word “hong” is used mostly for drying with low heat. A green tea made by using heat without steaming is called a “hong qing”. Somehow, however, finer teas that are baked avoid using that name; maybe because the name have been used widely by traders to refer to mass market baked green teas.

economic implication

And there is a good reason for it — baking is a process much preferred in mass production since it is easily automatable. A large percentage of export green tea and tea for scenting (1) is produced with this approach. Typically, the resultant products do not have the kind of aroma one gets from roasting or steaming, nor the freshness one gets from sun-drying. A not so strong character in the crude tea material is easier for subsequent added aroma.

- Kaihua Longding 開化龍頂 An orchid shape bake-set green tea from Zhejiang 20531 | 8773

- Huangshan Maofeng 黄山毛峰, original style, premium quality. This is perhaps the most famous baked green tea. Notice that it is more yellow than some other green tea.

- Luan Guapian 六安瓜片, one of the finest green tea varieties from the Anhui region

- Green Tea: Taiping Houkui 太平猴魁 This is a premium “bujian” class

- A green tea made from Taiwan wulong cultivars

adaptations in quality production

Unless, however, there is fine stepping in temperature progression or combination with roasting or high temperature quick baking, which are what makers of most finer baked teas use to distinguish their productions. Since finer teas are often made by smaller farms and definitely in smaller batches, the processes are done mostly in small semi-auto machines, or with traditional ovens. The skills of the master maker is thus crucial in rendering the desired character. That said, however, baked and sun-dried green teas are two subcategories which final virtue is a lot more dependent on the pluck quality, which is determined by the cultivar, the growing environment, pluck management and timeliness of the process.

Typically in finer productions, fresh plucks are quite immediately subject to heating with higher temperature, such as a quick roast of 180°C, to arrest any further enzymatic actions. Once the leaves are softened, they are shaped and then baked in a number of steps with intervals of cooling for the tea, lowering of baking temperature and progressive shaping.

As with any other manual methods, while the principal is the same, the manifestation can be entirely different and thereby, products of almost opposing characters. For example, the pungent green taste of Taiping Houkui (2), refreshing light body of Tianshan Yinya, and the warm heavier tones of Huangshan Maofeng are all products of “hong qing”. This diversity will not be possible with automation.